Water and Waste Management

There are 1.6 million miles of Water and Sewer pipes that currently need replacing in the US. Cast Iron, Steel, Copper, Concrete, PVC or HDPE [plastic] pipe are the choices being offered to replace our aging system, and each one has its pros and cons.

As always, the private sector will jump in where the People fear to tread, and some towns are now paying private sector prices for the basic need of safe running water. Time for Us to step in.

Two thirds of what is still under the ground is very old cast iron or steel. Plastic is lobbying hard and could end up with an 80% share of the next generation market. Some of that plastic is the same stuff we are trying to get rid of because it [allegedly] leaches dangerous chemicals into our food.

Sixty percent of the cost of water infrastructure is the pipes themselves, and even though PVC

has Health issues, it can be 30-70 percent cheaper than ductile iron (though ductile iron can

handle higher pressures and ranges of temperature).

We will not play politics with one of our most crucial basic needs. In order to make the best choice available, we need to consider:

- affordability

- sustainability

- compatibility with people and planet

Here is Our case for HDPE (High Density Polyethylene) pipe for all our needs (water mains, sewer mains, stormwater and drainage, electric and communications conduit):

- High impact resistance and flexibility makes it well suited for “dynamic soils” including earthquake prone areas

- High level of impermeability and strong molecular bond makes it suitable for high pressure pipelines

- Cost effective to install (can use cheaper installation methods) and have long term maintenance cost savings

- With fusion welded system, need for anchors / thrust restraint blocks eliminated, reducing material costs and installation time

- High durability (will last 50 – 100 years)

- Completely resistance to corrosion, considered a low-toxin plastic by environmental groups

- Less likely to have problems with root intrusion, keeps its integrity even when installed in unstable soils

- Has a very low thermal conductivity, so it can maintain more uniform temperatures.

- Has a relatively small carbon footprint when compared to iron and concrete pipe

- Because food grade polyethylene virgin material is used to fabricate HDPE pipes, they are safe for the transfer of potable water

- With its lower weight per foot, it is less costly to transport to job sites (ability to “nest” smaller diameter pipe within larger pipe)

- Corrugated HDPE pipe is already popular for storm sewers and highway drainage systems

- The fused joint creates a totally leak free system, and the ability to pull long lengths in trenchless installation practices, including HDD (Horizontal Directional Drilling), pipe bursting, and slip-lining [https://plasticpipe.org/municipal_pipe/advisory/sliplining/construction.html]

- Superior resistance to failure / rapid crack propagation (RCP). These are essential properties for HDD applications where scratching and gouging of the pipe are a fact of life. HDPE pipe can be gouged up to 10% (studies have shown even 20%) Nearly 90% of new pipe installation in Europe is HDPE (and those Europeans are pretty smart sometimes)

BOTTOM LINE: We can make this stuff ourselves, then charge ourselves enough to pay back the

Bank Loan + installation and maintenance costs + the Water Consumption Tax, and probably still pay less than We are now.

(Read More: HDPE Pipe)

“Waste Management” Side of The Equation

Human, Animal and Food Waste can create Energy.

We already have the ability to turn this waste into water and biofuel and a fertilizer byproduct (for our farming). The hope is that it might also be used to create Hydrogen (a cleaner fuel source) and possibly Graphite (that might be used in aluminum ion battery production) or Calcium Oxide / Hydroxide / Carbonate (all potential ingredients in “greener” cement)

Normally, Omni-processors (like the one pictured here) run about $1.5 Million. Our [possibly] more complex use of it could raise the price tag.

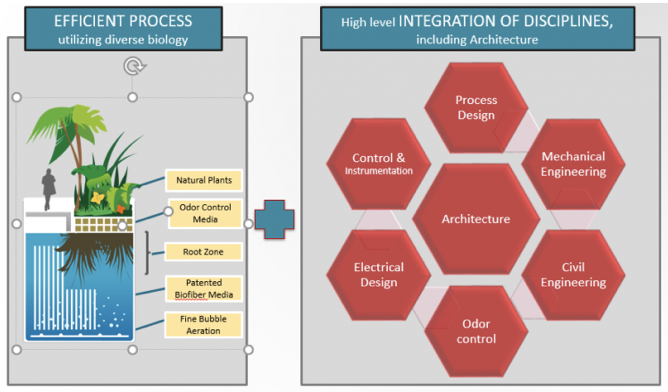

In order to put the Waste Management within the Community, it will need to be cleaner and greener. Organizations like Organica advocate biological membrane technology, where they “utilize active biofilms on natural (plant) and/or engineered root structures, all housed in a fully-enclosed, odorless facility”.

(Read More: The Organica Solution)

Our Communities will also need to utilize the newest “green technology” infrastructure to help curb the cost of stormwater surges. “Bioswales, retention ponds, pervious pavers and rain gardens mimic natural systems, absorbing storm water back into the ground (infiltration), using trees and other natural vegetation to convert it to water vapor (evapotranspiration) and using rain barrels or cisterns to capture and reuse storm water.” Actions like these intercept storm water before it ever enters the expensive-to-maintain “gray infrastructure” of municipal water and sewer systems.” Once we collect this stormwater, We also need to utilize it more effectively (toilet flushing, irrigation, laundry, etc.) “Conceptually, a water supply system should match the quality of water with the end use…in most of the developed world, high-quality potable water is used for all end uses. This approach wastes money and energy and imposes unnecessary impacts to the environment.

Our Water and Waste Strategy

- Create flexible systems that handle each Community’s unique geography, weather, etc.

- Create systems that are energy efficient (The “old school” way of doing it uses quite a bit of energy).

- Raise public awareness and “appreciation” of water (and air), which is easy to forget about until we don’t have it anymore.

- Create solutions that completely pay for themselves (and this means the true cost, with any negative side effects or indirect costs figured into the equation).

TAKEAWAYS

This is going to be a huge job for Communities. This is so big, We are going to bring more members onto our Department of Housing and Community Development Teams to help each Community best implement all this new infrastructure in a way that best suits their unique geography. Chemists, Biologists, Hydrologists, Ecologists and Physical geographers can all advise the Civil Engineers. We will also need people versed in Urban Agriculture, Mixed Use Development, and circumventing the current local zoning ordinances that are bound to get in the way.

And once We bring all these smart people together from their different “silos”, and they have worked together to come up with the “big picture” integrated solutions that will form our new holistic Communities, We will then insist they stick around and teach and train our children about all of it, in the hope they can light a fire under this next generation, who will be tasked to move the ball up the field even further.

Each Community can spend $2 Million for its Development Team, taken from the following roster:

ENGINEERS

- Electrical Engineer = $96,000

- Architectural Engineer = $139,000

- Materials Engineer = $86,000

- Structural Engineer = $82,000

- Mechanical Engineer = $88,000

- Civil Engineer = $88,000

- Project Engineer = $85,000

- Industrial Engineer = $86,000

- Environmental Engineer = $87,000

- Mining & Geological Engineers = $101,000

- Nuclear Engineer = $105,000

- Chemical Engineer = $120,000

- Waste Management Engineer – = $90,000

SCIENTISTS

- Physical Geographer – $90,000

- Geologist – $90,000

- Ecologist – $75,000

- Hydrologist – $120,000

- Chemists – $80,000

- Biologist – $90,000

OTHER EXPERTS IN

- Urban Mixed Use Development

- Urban Agriculture

- Communication Technology

- Zoning Ordinance

- Transportation

Water – 2014 – $109 Billion spent in US for infrastructure, $105 Billion from state and local, $4.4 Billion from Feds. Funding comes from federal grants, but mostly tax-free municipal bonds.

Water / Wastewater numbers

- $1 trillion over 25 years for water infrastructure

- $105 Billion a year for wastewater

Wastewater

14,748 wastewater treatment plants are the most basic and critical infrastructure systems for protecting public health and the environment. Years of treatment plant upgrades and more stringent federal and state regulations have significantly reduced untreated releases and improved water quality nationwide. It’s expected that more than 56 million new users will be connected to centralized treatment systems over the next two decades, requiring at least $271 billion to meet current and future demands. New methods and technologies turn waste into energy relying on the nation’s 1,269 biogas plants to help communities to better manage waste streams through reuse.

Water

An estimated 240,000 water main breaks per year in the United States, wasting over two trillion gallons of treated drinking water. According to the American Water Works Association, an estimated $1 trillion is necessary to maintain and expand service to meet demands over the next 25 years.

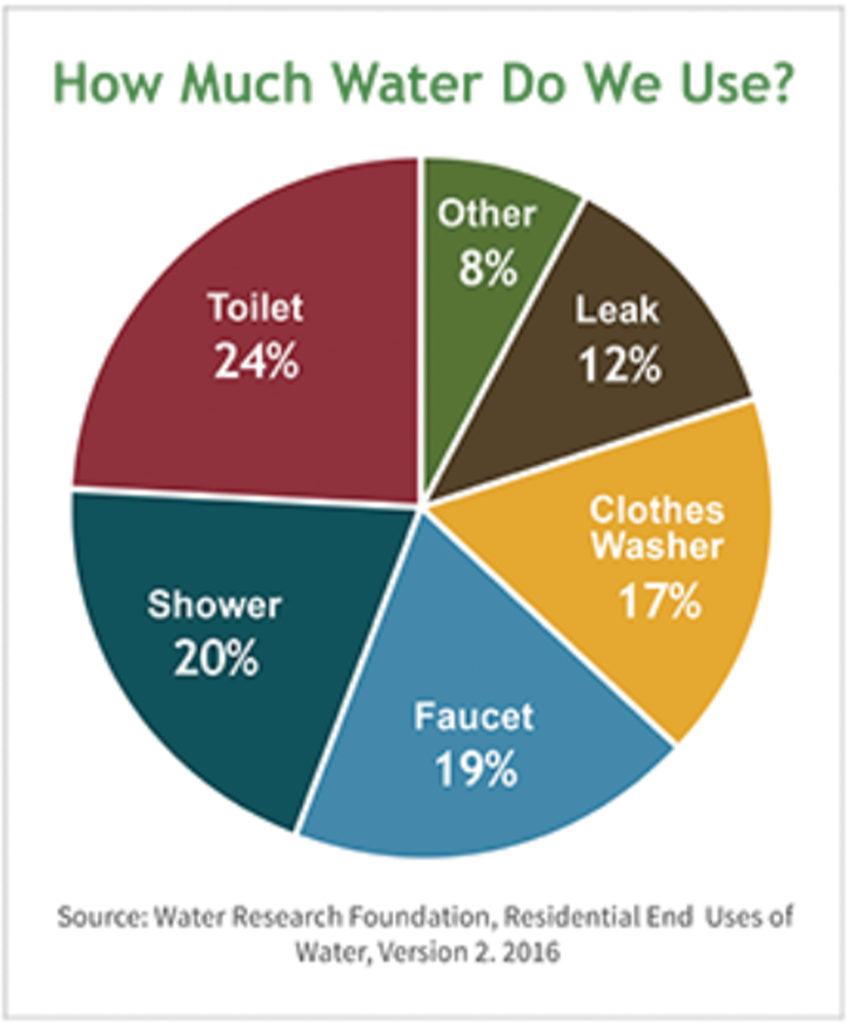

Two estimates – The average price of water in the United States is about $1.50 for 1,000 gallons [$0.0015 per gallon]. Another says $0.004 per gallon. In 2010, We used about 355,000 million gallons per day. “Each day in the United States, about 27.4 billion gallons of water are withdrawn and delivered from surface water and groundwater sources for residential use” https://www.neefusa.org/weather-and-climate/weather/home-water-use-united-states

ALL THINGS ENVIRONMENTAL (https://www.neefusa.org):

Statista – In 2018, the residential cost of water for a family of four using 150 gallons per person per day came to about 112 U.S. dollars per month (Read More: Statista Average Monthly Cost of Water)

Infrastructure

People are used to spending $0.00622 per gallon maximum. If I were to charge $0.002 per gallon more to help pay for infrastructure loan:

- 27.4 billion gallons per day use X 365 days X $0.002 = $20 Billion collected a year

- A loan of $348 Billion would cost $1.66 Billion a month or nearly $20 Billion a year in mortgage payments

- Condition of water/wastewater infrastructure – The American Society of Civil Engineers (ASCE) gave America’s infrastructure a“D” grade.

- Lack of public appreciation for the value of water

- Funding for capital improvement projects – More than 40 percent of non-utility respondents believe the water industry is not prepared to meet financial needs.

- Water scarcity/supply

- Replacing a retiring workforce

- Drought potential – Ten percent of respondents believe their home water service is not prepared for a drought of more than three years.

- Customer/community relations – Outreach is needed to communicate the challenges of water stewardship and develop public support.

- Recovering costs for service/investment – Eighty percent of utilities (water, wastewater, and combined systems) said they were not able to recover the full cost for providing service.

- Government regulations – Utility personnel ranked disinfection byproducts (DBPs) as the top regulatory concern, followed by pharmaceuticals and personal care products (PPCPs).

- Emergency planning and response

- Energy usage/cost

- Climate change – Only 20 percent of non-utility respondents feel the water industry is prepared for climate issues such as risk and resiliency.

- Utility security – Worries include intentional water contamination and cybersecurity.

HDPE VS PVC

HDPE (high-density polyethylene) protect and preserve natural resources. HDPE pipe fits this need exceptionally well.

HDPE pipe has a relatively small carbon footprint when compared to iron and concrete pipe. A study conducted in the late 1990s concluded that plastic pipe used in the building, construction and transportation industries required 56,500 trillion fewer BTU’s than iron and concrete/aggregate alternatives.

With its lower weight per foot, HDPE pipe is also less costly to transport to the job site than metal or concrete. And with the ability to “nest” smaller diameter pipe in larger pipe, more feet per truckload can be delivered with out breeching highway weight limitations.

HDPE

HDPE is used in butter tubs, milk jugs, juice, household cleaner and shampoo bottles, as well as cereal box liners and grocery bags. It is often considered a low-toxin plastic, but like almost all plastics, it has been found to release estrogenic chemicals.

In one study, 95 percent of all plastic products tested were positive for estrogenic activity. This means they can disrupt your hormones and even alter the development of your cells, which puts infants and children at even greater risk. In this particular study, even HDPE products that were free of bisphenol-A (BPA) still tested positive for other estrogenic chemicals. Use with caution.

PVC (polyvinyl chloride)

PVC is used in plastic cooking oil bottles, deli and meat wrappers, shrink wrap, sandwich baggies, and plastic “saran” wrap. It is also found in plastic toys, lunch boxes, table cloths and blister packs used to hold medications. And it is commonly used to make jewelry and faux-leather purses, shoes and jackets.

PVC contains numerous toxic chemicals including lead and DEHP, a type of phthalate used as a plastics softener. As if the lead weren’t bad enough, phthalates are considered “gender-bending” chemicals which cause the males of many species to become more female. These chemicals disrupt the endocrine systems of wildlife, causing testicular cancer, genital deformations, low sperm counts and infertility in a number of species, including polar bears, deer, whales, otters, and frogs, among others.

Scientists believe phthalates cause similar harmful effects in humans. If your home has flexible vinyl flooring, or those padded play-mat floors for kids (often used in day cares and kindergartens, too), there’s a good chance it is made from toxic PVC. PVC flooring has also been linked to chronic diseases like allergies, asthma and autism.

PVC is one of the worst health and environmental offenders. Avoid at all costs.

Every underground utility and application where pipe is used, we have structured our organization into five divisions: Fuel Gas, which focuses on the natural gas distribution industry; Municipal and Industrial, which focuses on potable water and sanitary sewer (that’s the municipal side) and all other industrial applications which can include mining, landfill, geothermal, oil and gas gathering to name a few; Corrugated Pipe, which covers stormwater systems, storm water management including retention and detention systems, sub-surface drainage and agricultural drainage for maximum crop production; Conduit, which serves the power and telecommunications industries for underground service lines; Heating and Plumbing, which covers radiant heating systems and indoor residential plumbing including hot and cold water lines.

In HDPE pressure pipe systems, the fused joint creates a totally leak free system. This means precious natural resources are saved and the energy to treat, store and distribute water is reduced. For municipal storm water systems, improvements in joint design in corrugated HDPE pipe deliver a watertight joint that equals and exceeds the performance levels of sanitary sewer systems. This means infiltration or exfiltration that can prematurely end a storm water system or cause road damage due to sink holes, is dramatically decreased.

When it comes to long-term sustainability, HDPE pipe truly shows its key benefits: it doesn’t rust, it’s highly resistant to mineral tuberculation and its abrasion resistance is significantly greater than metal, concrete and other plastics. With today’s crumbling underground infrastructure experiencing nearly 700 water main breaks per day (might want to sight a reference for this number), the need to replace old technology becomes even more important.

The choice of material will dictate the service life of the system. What affect will the flow have on the pipe material? Is it highly acidic or alkaline? Is it abrasive in nature? What about the soil conditions? “Hot” soils can immediately begin to attack the exterior surface of the pipe. And what about soil contaminants?

In any of these instances, a material that is highly resistant to these conditions must be employed.

Next, one needs to understand the installation methods to be used, trenchless or open cut? With HDPE pipe’s fused joint, a monolithic pipe string is created allowing for long pulls and minimal surface (and traffic) disruption.

Lastly, what is the lifetime cost of the system? Will special corrosion protection be needed? Will the pipe have the same flow characteristics in 10, 50 or 75 years? What is the anticipated cost of water (or other fluid) loss through mechanical joints? What will be the effect of soil infiltration on roadways whose cost to repair far exceeds the cost of the pipe?

Sustainability, service life, and lifetime costs – this is the triple bottom line that today’s design engineer needs to address. Is it the best choice for the environment in terms of energy costs (carbon footprint) and protection for natural resources? Is it going to last for multiple generations – and then some? What is the total economic cost, including manufacturing, delivery, installation, operation, maintenance and performance for the owner/operator? HDPE pipe, both pressure and gravity flow, has proven itself around the world as the best material choice for water, sanitary sewer, storm sewer, natural gas distribution, mining, oil & gas gathering, drainage, buried conduit, outfall lines, and now even safety systems for nuclear power plants. Its inherent resistance to rust and abrasion along with the best joint in both pressure and gravity flow applications has made HDPE pipe the one plastic material used in all underground utilities.

Because of its flexibility and durability, HDPE pipe has been the material of choice for trenchless installation practices almost since the technology first appeared in the mid- to late-1960s. Furthermore, since a fused joint produces a monolithic pipe string, the ability to pull long lengths and use all trenchless installation practices including HDD, sliplining and pipe bursting favors the use of HDPE pipe. Since HDPE pipe has enjoyed such a long acceptance in trenchless applications, there has been significant research and studies to provide the design engineer and contractor confidence in application and installation. As an example, there are several documents available for the design and installation of polyethylene pipe by directional drilling.

Another fundamental reason why HDPE pipe is so widely preferred for trenchless applications is that it has the strength to handle this demanding installation practice. Since HDPE pipe is extremely tough it can withstand the rigorous trenchless installation process and is not affected by scratches and gouges (10 percent of the pipe wall) that are certain to occur. Other materials are more sensitive to this type of damage which will cause premature failure of the piping system. HDPE pipes have the physical properties to handle large pulls.

HDPE resin and pipe have superior resistance to failure and rapid crack propagation (RCP). These are essential properties for HDD applications where scratching and gouging of the pipe are a fact of life.

HDPE pipe can be gouged up to 10 percent (studies have shown even 20 percent) of the wall thickness with no detrimental effects to the long-term performance of the pipe. Resistance to RCP means that the monolithic piping system of heat fused HDPE pipe will not be susceptible to rapid cracking that can run for hundreds or even thousands of feet with catastrophic results.

Continued improvements in pipe design, specifically in the corrugated drainage pipe industry (storm water management) has allowed for greater burial depths and improved joint performance. Today’s

HDPE corrugated pipe is significantly better than the original product first introduced in the mid-1960s. State and federal Departments of Transportations, municipalities and private enterprises are the beneficiaries of these efforts.

PVC and HDPE are the top pipe choices in the trenchless market today. We ask their advocates why.

Stating their Case: PVC vs. HDPE

PVC and HDPE are the top pipe choices in the trenchless market today. We ask their advocates why.

- https://trenchlesstechnology.com/stating-their-case-pvc-vs-hdpe/

- https://www.pepipe.org/members

- https://plasticpipe.org/index.html

- https://plasticpipe.org/pdf/2014-texaswater-poster-saws-rcp.pdf

HDPE pipe, in our opinion, is the best product for developing a truly sustainable infrastructure. From its low energy cost to produce, ship and install, to its superior joint performance in all applications, to its resistance to rust and abrasion and finally its short and long term economic advantages, we believe there is no other material that approaches the performance and versatility of HDPE pipe.

Uni-Bell PVC Pipe Association executive director Michael Luckenbill and Plastic Pipe Institute executive director Tony Radoszewski

- Polyethylene (PE) and polyvinyl chloride (PVC) are the plastic pipes most often used for underground utility construction.

- Some in the PE market estimate that 90 percent of the natural gas pipe installed historically decade is PE pipe.

- PVC proponents claim that more linear feet of PVC water and sewer pipe is being installed today than all other types of pipe combined.

- PE and PVC have several characteristics in common, but also significant differences. Both are light in weight, do not corrode and are resistant to chemical and bacteriological buildup. PE is more flexible than PVC. A primary difference is the way lengths of pipe are joined together and to other pipe materials. Compressed air or gases ought to not be introduced in to PVC pipes.

- The Plastics Pipe Institute (PPI) represents manufacturers of PE pipe and actively promotes the use of PE products. The Uni-Bell PVC Pipe Association does the same for member companies who manufacturer PVC pipe. The sections that follow summarize characteristics of the two types of pipes and are based on information provided by the two associations.

Polyvinyl Chloride (PVC) Pipe

PVC is widely used for:

- * Water mains and service lines;

- * Sewers

- * Irrigation

- * Conduit and duct

- * Drain, waste and vent pipes, and

- * Various industrial applications.

PE pipe is used for a variety of applications, including distribution of pressurized natural gas, pipelines carrying petroleum and petroleum products and chemicals, underground loops for geothermal heating and cooling systems, distribution of compressed gases and air, potable water mains and service lines, and sanitary and storm sewer systems. Corrugated PE pipe is used for storm sewers and highway drainage systems.

High-density polyethylene (HDPE) conduit is the preferred material to house and protect electrical power and telecommunications cables within. It offers unmatched corrosion and chemical resistance, is flexible and durable, and is available in long coil lengths to reduce joints and installation time. HDPE conduit is available in a variety of sizes, colors, dimensions and lengths. HDPE is also used for cable-in-conduit conductors.

Conduit inside buildings

Typical applications include Power Utilities, Telecommunications, CATV, SCADA, FTTH, ITS, highway lighting, and other underground utilities. Premise (Riser and Plenum) conduit has specific characteristics and flame retardant ratings for use as nonmetallic raceways in buildings. HDPE conduit is installed using methods such as Horizontal Directional Drilling (HDD), plowing and laying in open trenches.